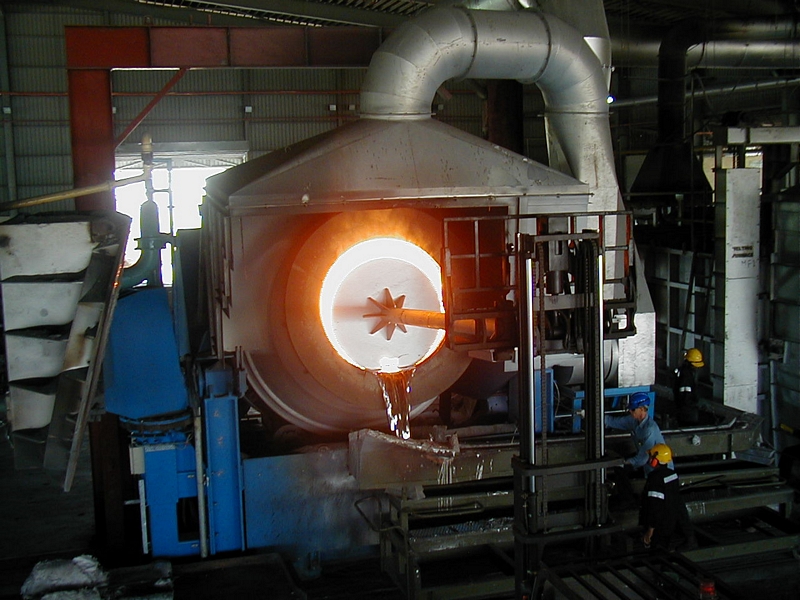

Rotary Melting Furnaces

Furnace Engineering's Dross Rotary Furnaces are the "Rotating Closed Well" type, combining the advantages of rotaries, reverbs and dry-hearth furnaces in a single unit. Applications for Rotary Furnaces are: Melting of Zinc & Aluminium and Smelting of Lead, Tin, Bismuth and Rare Earth.

Key features:

- Melts a wide range of metals and feed-stock including:

- Dross, Scrap or Foundry Returns

- Eliminates metal pollution by trace elements

- Facilitates charge mixing

- Self-Cleaned lining

- Low energy consumption and high thermal yields

Other design features:

- Rotating unions

- Onboard control panel, power pack & air blower

- Self supporting chassis

- Positive & direct drive

- Vari-gas burner control system

- New generation temperature control

- Combustion equipment

- Air-fuel (gas or oil) burners

- Oxy-fuel (gas or oil) burners